Home > Services > Digital factory > Virtual Commissioning

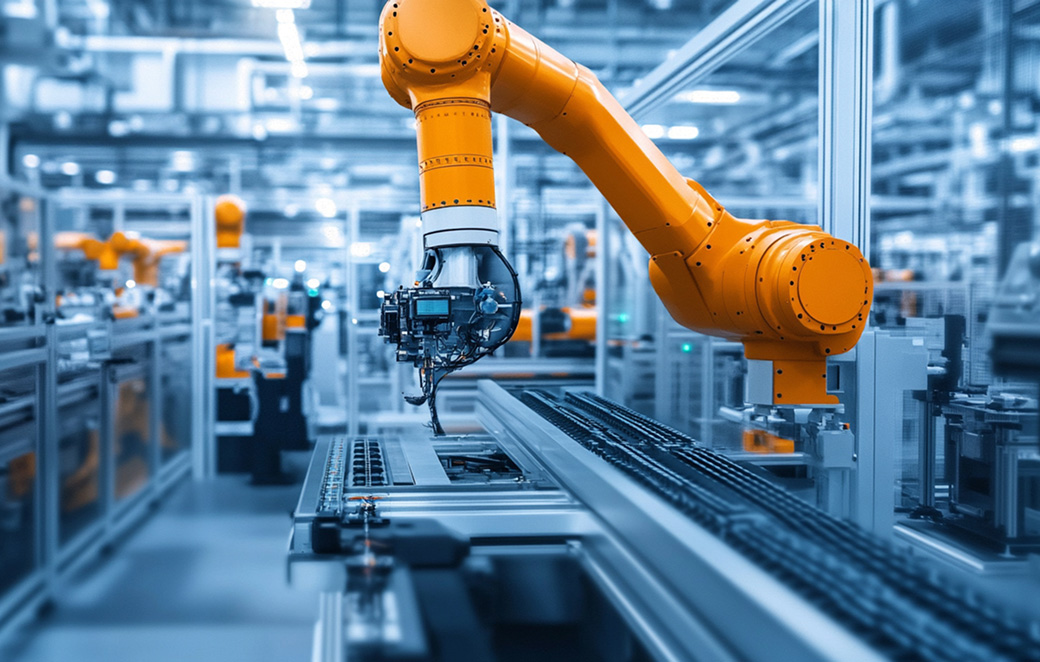

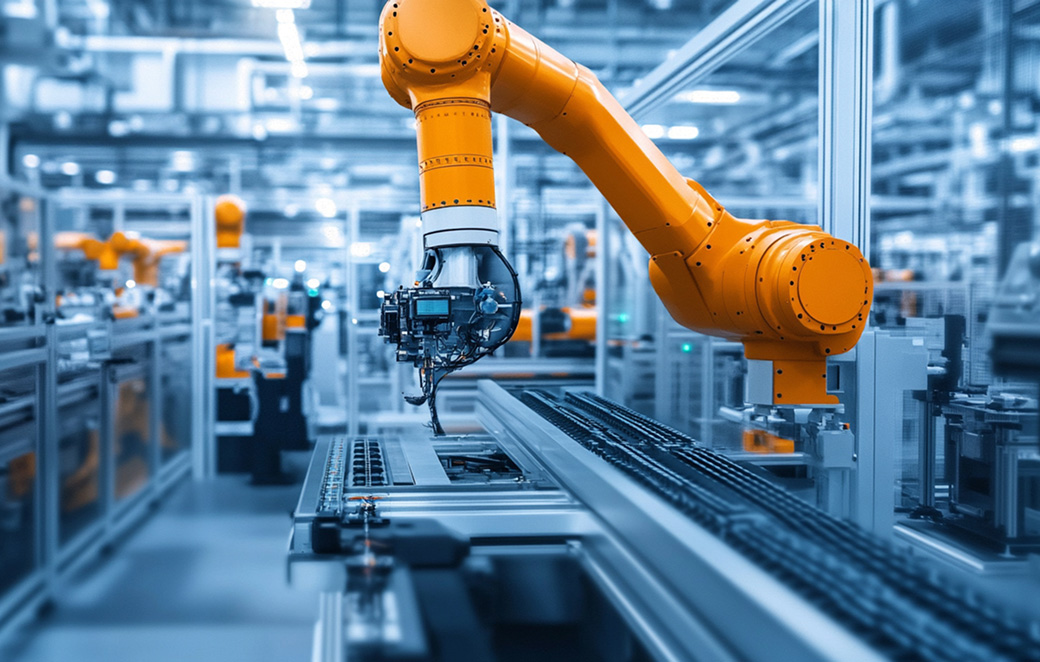

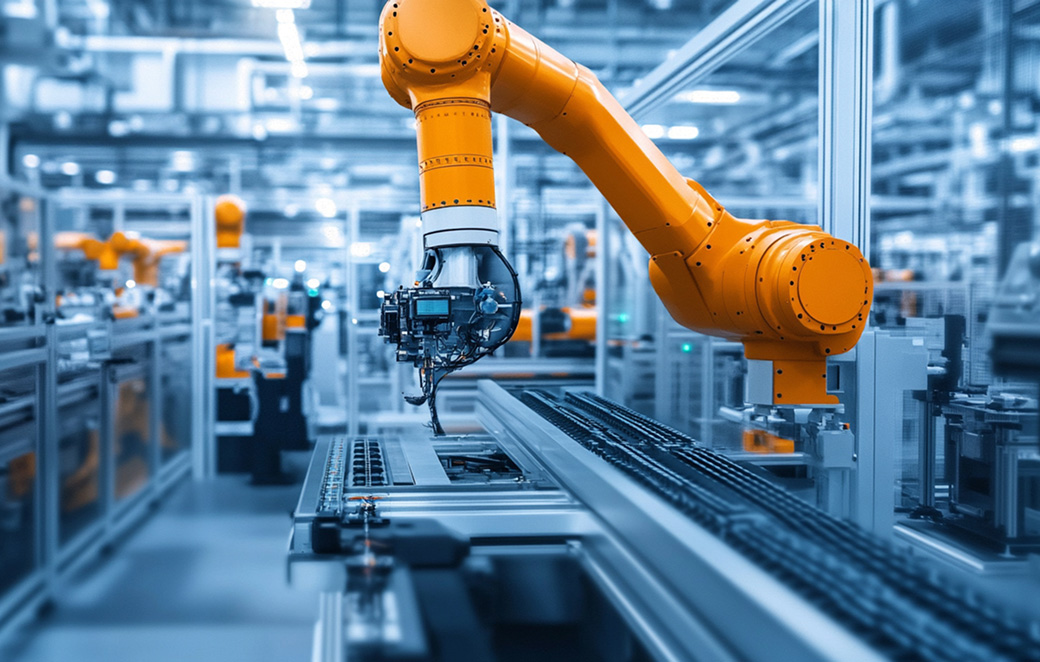

Our virtual commissioning technology transforms production planning by enabling systems to be simulated, validated, and optimized before any physical components are installed.

As a result, you benefit from error-free deployments, accelerated schedules, and significantly reduced implementation costs – all driven by intelligent digital foresight.

Virtual commissioning allows PLC and robot programs to be debugged and tested in a digital environment.

This ensures that your automation software is fully validated before deployment to physical hardware. Moreover, control logic can be integrated and tested under real-world conditions.

Safety systems are also virtually verified, ensuring compliance with standards and reducing commissioning risks.

By simulating mechanical, electrical, and pneumatic processes, we validate system functionality early in the design phase.

In addition, digital twin technology provides deep insights into real-world behavior. This enables early error detection and reduces inefficiencies.

Factory Acceptance Testing (FAT) is conducted virtually, ensuring your systems meet all requirements before going live.

Cycle Time Verification helps identify bottlenecks and optimize production throughput before commissioning.

Furthermore, energy and throughput optimization reduce consumption and improve sustainability during the planning phase.

Post-deployment feedback enables continuous improvement by refining digital models and improving overall system performance.

Virtual commissioning allows PLC and robot programs to be debugged and tested in a digital environment.

This ensures that your automation software is fully validated before deployment to physical hardware. Moreover, control logic can be integrated and tested under real-world conditions.

Safety systems are also virtually verified, ensuring compliance with standards and reducing commissioning risks.

By simulating mechanical, electrical, and pneumatic processes, we validate system functionality early in the design phase.

In addition, digital twin technology provides deep insights into real-world behavior. This enables early error detection and reduces inefficiencies.

Factory Acceptance Testing (FAT) is conducted virtually, ensuring your systems meet all requirements before going live.

Cycle Time Verification helps identify bottlenecks and optimize production throughput before commissioning.

Furthermore, energy and throughput optimization reduce consumption and improve sustainability during the planning phase.

Post-deployment feedback enables continuous improvement by refining digital models and improving overall system performance.

Debugging and testing allows PLC and robot programs to be debugged in a virtual environment, ensuring that the software is error-free before it is deployed on physical hardware.

Control Logic Integration enables the integration and testing of PLCs and robot controllers with a digital model, simulating control sequences and system behaviour under different scenarios.

Safety systems are validated virtually, ensuring compliance with industry standards without the need for physical hardware.

Simulation of mechanical, electrical and pneumatic processes to validate functionality before implementation.

The use of digital twin technology provides insight into real-world behaviour, enabling early detection of errors and inefficiencies.

Factory Acceptance Testing ensures systems meet requirements by virtually validating processes, reducing the risks associated with traditional commissioning.

Cycle Time Verification checks cycle times and identifies bottlenecks to optimise production efficiency.

Energy and Throughput Optimisation allows virtual optimisation of energy consumption and throughput times during the design phase.

Continuous Improvement through post-deployment feedback is used to refine digital models and further improve system performance.

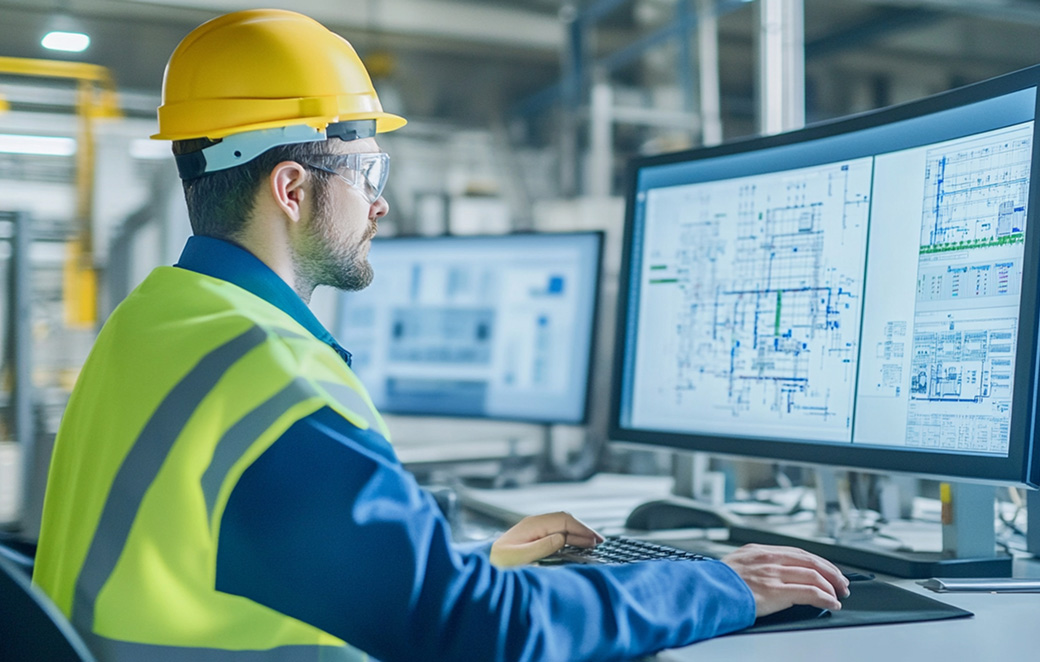

We support your pilot projects with expert guidance and close collaboration. This enables your team to successfully implement virtual commissioning, even when tackling complex challenges for the first time.

By partnering with our expert teams, you gain access to specialized skills and advanced technologies. As a result, your automation process becomes faster, more reliable, and tailored to your exact requirements.

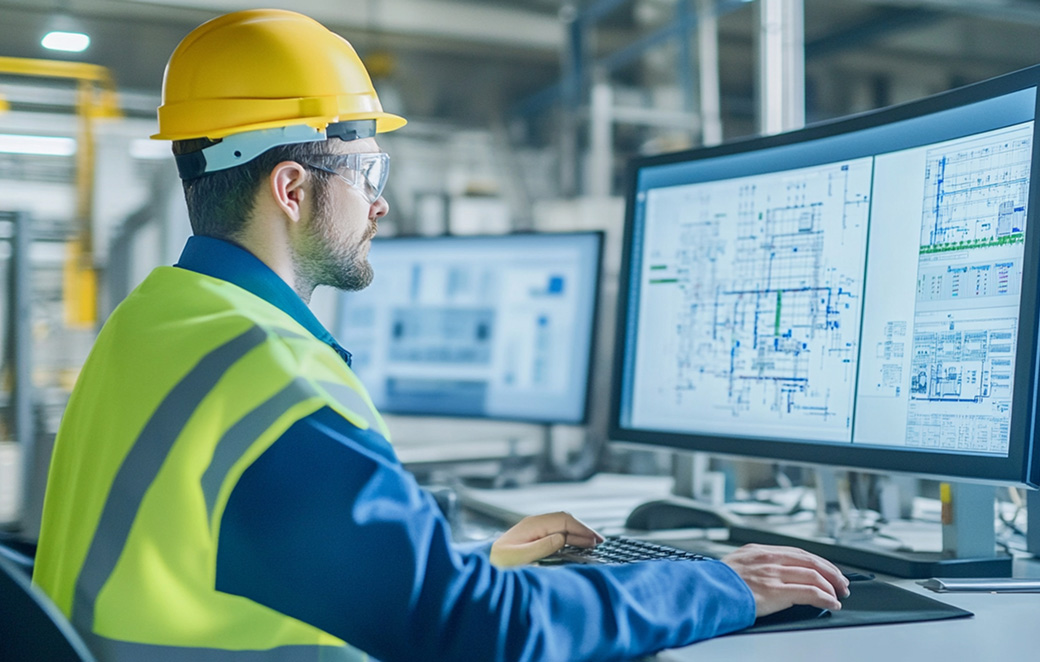

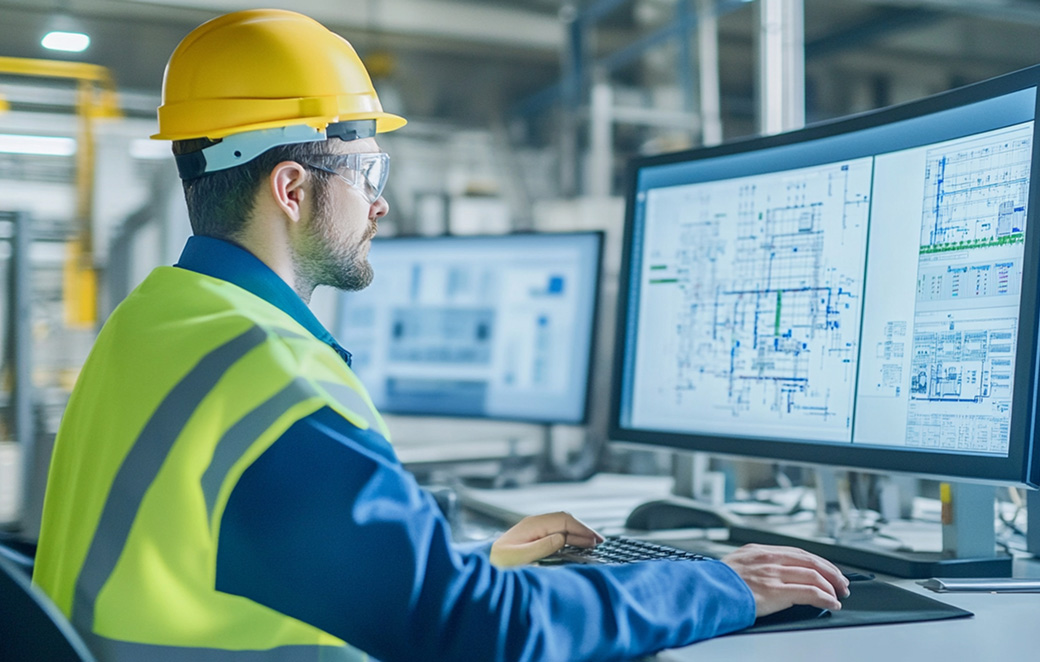

We begin by analyzing your existing engineering workflows to define clear goals for virtual commissioning.

Next, we create digital twins, run simulations, and automate key tasks. Throughout the process, we promote cross-functional collaboration and use ROI-driven testing strategies.

Ultimately, this improves your engineering performance and maximizes the benefits of working in virtual environments.

Engineering Workflow Optimisation

Best in class virtual commissioning toolset

Have a project in mind?

Digital factory Modeling

Want to recieve our newsletter?

Find us at

China,

Shanghai

Germany,

Weingarten

Bosnia,

Tuzla

India,

Bangalore

Montenegro,

Podgorica

China, Shanghai

Germany, Weingarten

Bosnia, Tuzla

India, Bangalore

Montenegro, Podgorica

We use cookies and other tracking technologies to improve your browsing experience on our website, to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from.